Insulation is critical for keeping buildings energy efficient and comfortable at the same time Many different types of insulation are used in buildings with EPS being one of the most popular types due to its thermal performance and versatility.

Comparing different types of insulation requires comparing their respective R-values to determine how much of a given type of insulation is required to meet the insulation requirements of a building or project. While EPS has impressive performance characteristics as an insulator, it has many other performance characteristics as well that make it a top choice among architects and engineers.

What is EPS Insulation?

Expanded Polystyrene (EPS) insulation is a type of closed-cell foam insulation. Made from polystyrene beads expanded using pentane, EPS insulation offers a rigid and lightweight solution to many insulation needs.

When EPS is manufactured, polystyrene cells are expanded and closed off while still filled with air. The resulting product consists of air captured within the expanded polystyrene. The resulting board of insulation is lightweight and strong, and blends the characteristics of air and polystyrene. Recognized for its consistent performance, durability, and broad application range, EPS has been a trusted choice for architects, builders, and homeowners for many years.

Understanding R-Value

The term "R-value" is thrown around a lot in the insulation world, but can be meaningless without a good understanding of what it truly represents. In simple terms, the R-value measures an insulation material's resistance to heat flow. A higher R-value indicates a material with better insulating properties.

Many insulation materials are listed with an R-value per inch of thickness. With this parameter, it is easier to compare how much of a given material would be required to achieve a desired R-value. A material with a low R-value per inch means it would have to be much thicker to insulate, as well as a thin material with a high R-value per inch. It's a key metric for anyone looking to ensure that their homes or buildings are energy efficient, and it provides a clear indication of how well a material will keep warmth in during the winter, and out during the summer.

The R-Value of EPS Insulation

The R-value of EPS varies based on its density, but it typically ranges between R-3.9 to R-4.4 per inch. This means that EPS insulation provides excellent thermal resistance, which makes it a superior choice for those seeking to optimize energy efficiency in their projects. Its consistent R-value, unaffected by age, guarantees long-term performance and peace of mind.

Benefits of EPS Insulation Beyond High R-Value

While EPS boasts an impressive R-value that makes it a great candidate for insulation, EPS also has a host of other attributes. Some of these characteristics include:

Cost-Effective

EPS insulation is an affordable solution that doesn’t compromise on performance. Its high R-value per dollar means you're getting a great deal on energy savings in the long run.

Lightweight

Due to its cellular structure, EPS is remarkably lightweight, which makes transportation, handling, and installation a breeze. Workers can install many EPS panels without quickly tiring since the panels are mostly air.

Ease of Insulation

EPS can be easily cut and shaped to fit a variety of applications, which reduces installation time and helps to ensure a snug fit. Workers also do not usually need special skills in order to install EPS insulation.

Moisture Resistance

EPS's closed-cell structure provides excellent moisture resistance and protects against mold and water damage. EPS foam performs well in damp locations where other types of insulation may not.

Long Lifespan

With proper installation, EPS insulation can last for decades, for consistent thermal performance throughout its life. EPS insulation requires little to no maintenance for the life of the structure when properly installed.

Environmental Friendliness

EPS is recyclable and produces minimal waste during manufacturing, which makes it an eco-friendly choice. Even the expansion agents, typically pentane, used during production have low GWP to minimize the impact on the environment.

Compressive Strength

Despite its lightweight nature, EPS boasts impressive compressive strength, so it is suitable for applications that require resistance to load-bearing forces.

Fire Performance

While not fireproof, EPS insulation is treated with fire retardants that provide resistance to the spread of flames.

Thermal Stability

EPS maintains its R-value and insulating properties even in extreme temperatures for consistent performance.

Versatility

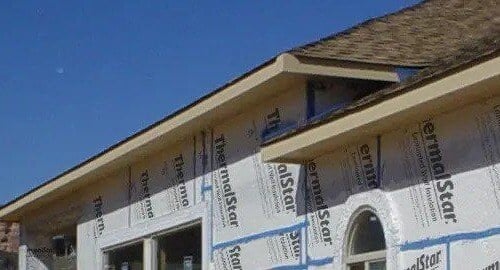

From roofs to floors, walls to foundations, EPS's adaptable nature makes it suitable for a vast array of applications.

EPS is Easy to Spec on Acelab

Acelab is a materials platform that makes architecture better for architects. Our tools enable you to discover, compare, and specify the right materials for your project quickly and easily. Break the cycle of reusing specs and find the best products for your needs, every time.

With Acelab, users get access to intelligent product recommendations, comprehensive product data, technical specifications, and CAD details from leading manufacturers. Plus, all the tools needed to manage, share, and collaborate at each step.

Make a free account and get instant access to our tools and resources.